Worksample | 2024

[Curated September, 2024]

Focused on Visualization, Fabrication, and Design Skills.

Visualization Examples

[Rendering In Blender | modeling involves Blender, Rhino, & Houdini]

Completed between 2018 & 2024

To the right is a collection of rendered images from Blender with a focus on realism. Each project has varied requirements and timelines, so the level of detail and lighting naturally varies. Some were made for digital viewing only, others for print, and some during the process of preparing something for fabrication/manufacturing. Meaning, some are modeled for the sole purpose of visualization, while others are modeled with the intent and accuracy required for producing drawings and 3D files for fabrication (3D printing, CNC Routing, Laser cutting, etc).

Please note that some images may appear blurry at first while it loads the high-res image. This can vary based on your connection.

Ferrari 2024

[experiential Desing | Creative exercise]

Completed in Summer 2024 | 2 Weeks

This design exercise was taken on to explore designing a space, elements, and atmosphere for a luxury brand while utilizing new fabrication technologies. The project was completed from scratch within 2 weeks. The brief was focused on a cocktail reception for Ferrari showcasing their new ‘24 line-up utilizing a Uniflex Tent structure on the beach in Miami. Certain qualifiers were a dark, luxurious atmosphere, entrance moment, and uniquely engineered elements.

The main entrance takes some design language from some of Ferarri’s cars. The walls are designed using parametric software to be built using a combination of traditional methods and CNC-cut parts. Everything is meant to be modular for transportation and quick assembly and break-down.

The central bar is another key element, taking advantage of cutting-edge, large format Robotic 3D printing such as that from Nagami. Each side is made up of four modular parts with integrated storage and an integrated lighting element on the front, nodding to their new “pencil line tail-light” design.

Everything was modeled with a combination of Rhino/Grasshopper + Blender. All drawings were completed using Rhino + Illustrator, and renders were done with Blender.

NEUTRA

[minimal design | quality materials]

Completed in 2019

The Neutra Table was designed originally to add storage to our small New York apartment. The piece disassembles and packs flat with ease; each fastener a highlighted detail, exposing everything to the owner about it’s assembly. One sheet of 25mm Baltic Birch Plywood, 12 Brass Bolts into Stainless Steel Threaded Inserts with Sapele Mahogany details. It has traveled several times and continues to serve our home well to this day.

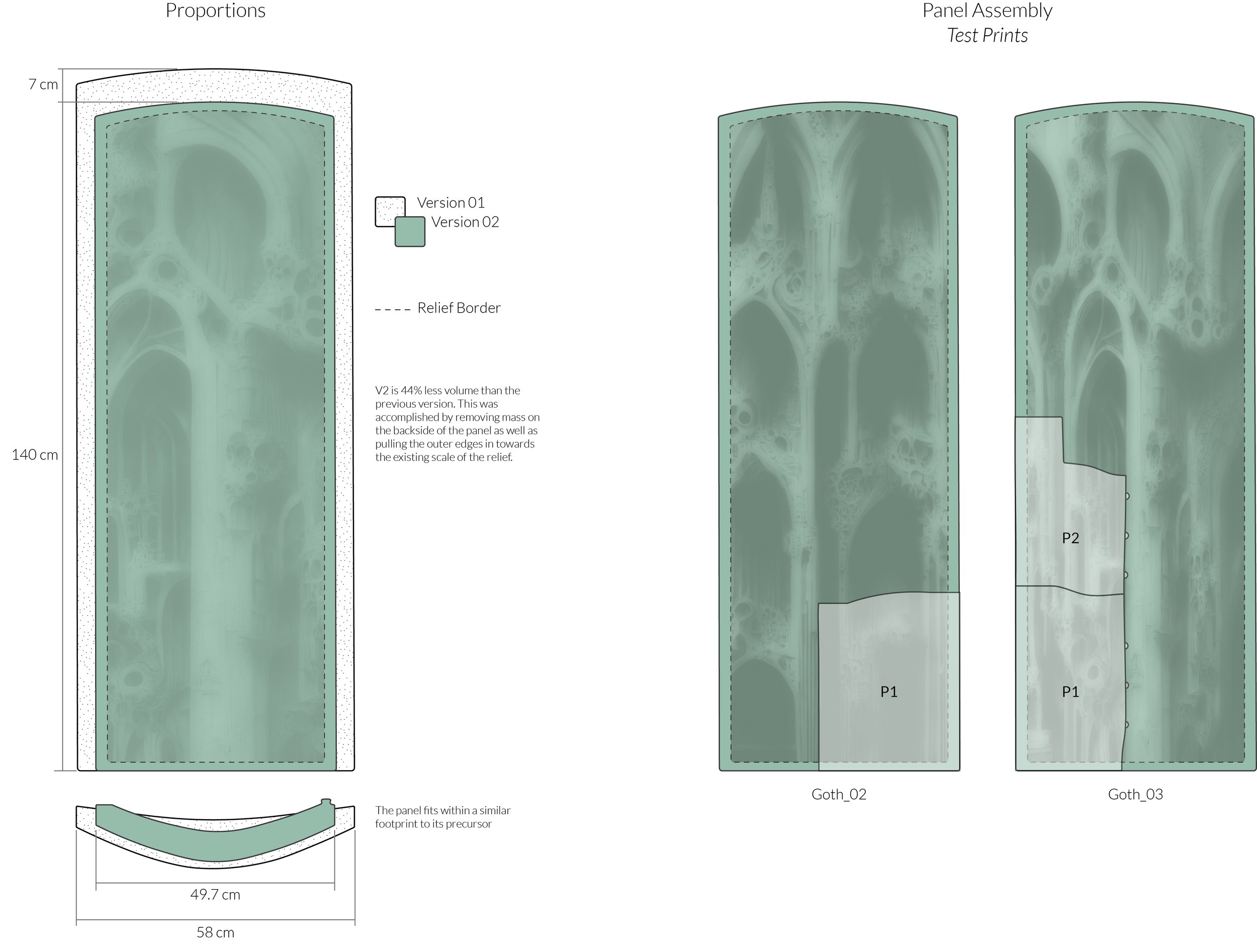

Gothic Reimagined

[3D Printed Stone]

In collaboration with Dustin White & Concr3de [September 2022]

For the massive stone convention MARMOMAC in Verona, Italy, Concr3de is a newcomer to the space. Their primary goal is to harvest the waste from the stone industry and through additive processes rather than subtractive ones, give it a new life in the most efficient way possible.

Concre3de reached out to us to design a set of center pieces for the convention that would showcase the capabilities of their new 3D printers. Dustin White developed a set of images taking influence from gothic architecture and together we turned those images into a pair of 3D printable “columns”. Each face contains one of four images. That was then broken into a set of parts that key together atop one another forming a panel. Two panels dovetail into one another to form a double sided column sitting around five feet tall and weighing in around 800lbs each.

Column #1 of 2 | Four total images in two pairs. Two columns were made with each face having a relief of one image.

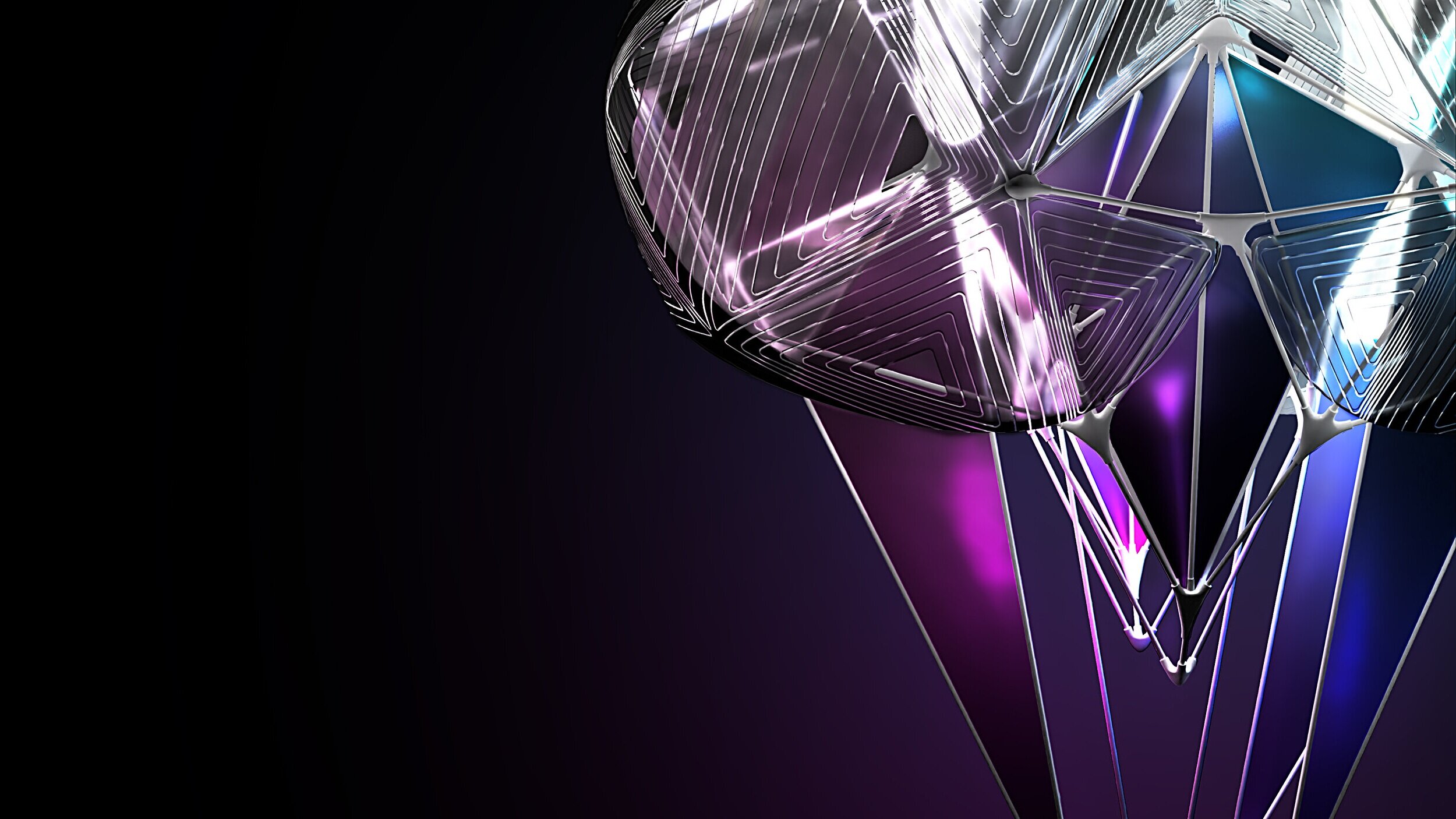

KALEIDOS

[Fabrication in PRogress]

In collaboration with Dustin White & Design Morphine

This contemporary Chandelier [5’ x 3.8’ x 5’] was designed for Jump Into The Light, a company in NYC that is home to an array of VR/AR based experiences. This interactive installation implements an digital process developed in-house to create clean, 3D printable joints for complex structures. These Nodes are printed in Onyx, a proprietary reinforced plastic from Markforged, with additional fiberglass reinforcement where necessary. Our friends at Design Morphine are creating custom interactive LED lights that will push color off the reflective, chromatic panels on the interior. Dustin White’s personal process for creating intricate plastic netting via laser-cutting and hand forming will act as a diffuser around the main body of the chandelier.

Antique Hardware

[Replication Via 3D printing]

In collaboration with Moon Jelly

In the film industry a variety of hardware is sourced for most films, especially period pieces. Not only are these unique items usually quite expensive, but they can be slow to source as well. On top of this, while some pieces may become assets to a studio and be kept for years, most things on films sadly disappear or get disposed. Our solution was to utilize resin 3D printing (SLA) and the power of 3D modeling to create a growing collection of replica parts that are based on real era accurate hardware. The printers can utilize a variety of resins with different properties for different uses, and with a few edits on the computer they can go from brand new to scratched, weathered and aged all before printing and painting. They are even durable enough to be fully functional on a set, and for a fraction of the cost.

FILM + EVENTS

[working in a fast-paced shop]

- CNC Routing | 3D Printing | Vacuum Forming | 3D Modeling & Drafting | Coordinating | Experimenting

[Jan 2021 - March 2024]

Over the past few years, a majority of my time has been spent in a fast-paced production environment with a team of talented fabricators. Mostly focusing on film (Movies, TV, and commercials), the goal was often to create a convincing illusion, however, we produced permanent high-quality work as well. This gallery attempts to capture a snapshot of this time and the variety of projects we worked on. My role in this team has been a flexible one. Serving as the sole operator of the digitally controlled equipment, and the only in-house drafter/3D Designer, I often switched between a coordinator, designer, and fabricator.

TITANIC STAIRCASE

[Replica set, fully modular, fabricated in 3 months]

- Fully modeled in Rhino, all drawings for fabrication were produced during the process of modeling and building

[December 2023 - Beginning of March 2024]

Working alongside a fabrication crew of about twelve people, we produced a replica set of the Titanic Staircase for EM Group. The set is fully modular, to be taken apart, shipped worldwide, and showcased in museums as part of a larger exhibition. We were supplied with over ten-year-old drawings, all which were very inaccurate. I produced a full 3D model of the set, working alongside lead fabricators to nail down details and assembly order. Throughout the process, I produced shop drawings for all team members and external sub-contractors. I also produced and programmed all files for CNC routing, 3D printing, and laser cutting. Overall, the team nailed it. In the end, our scenic crew came in and faux-painted all the parts that couldn’t be made of real oak or marble which really brought it to life.

Here are a selection of images showing it off. There’s too much material and detail to capture it all here properly.

Showcasing the completed model used during the build. All shop drawings were produced from this file. Software: Rhino + Grasshopper